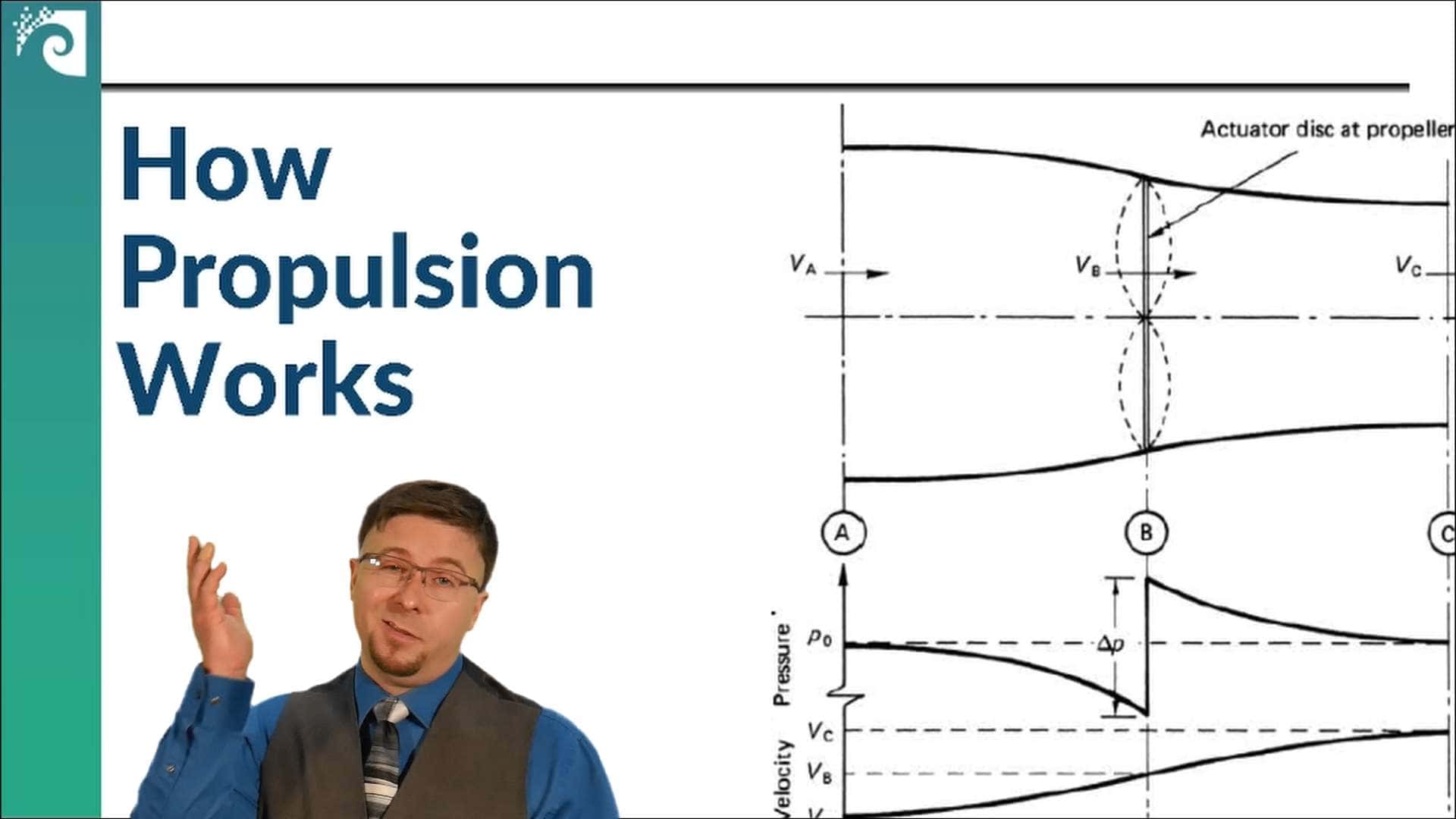

The pressure difference is where we convert the power of a rotating shaft (engine power) into some type of fluid power that generates thrust. Think of it like injecting energy into the flow stream. The pressure difference normally comes from some type of rotating foil section. One side of the foil generates a higher pressure, and the other side generates a lower pressure. This is the fundamental physics behind your basic slow speed propeller. But as the ship velocity increases, we need to increase propeller RPM to keep up.

The higher RPM speed introduces new problems. As the propeller foils rotate faster, centrifugal force dominates flow. This centrifugal force pushes the water radially out from the center of the propeller, which is a problem. Propeller foils don’t work when the water runs radially along the blade. The water throws out sideways and generates no pressure difference.

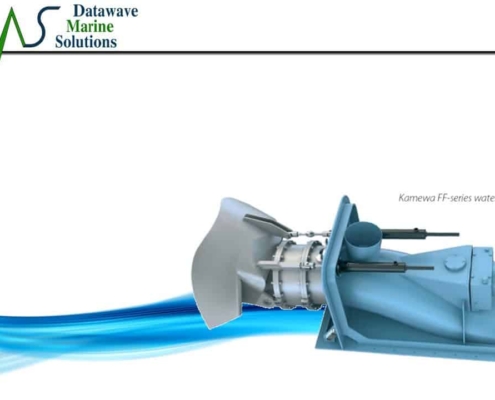

One solution is to enclose the propeller inside a long tube. We call this an impeller. The walls of the tube trap the water flow. Now, we can use the centrifugal force to our advantage. It becomes the second method of generating a pressure difference.

The final option for pressure difference is to change the density of the fluid, which tends more into the field of thermodynamics. Combustion on rockets or jet engines creates rapidly expanding gases. That rapid expansion generates a massive pressure difference. Unfortunately, combustion does not work well underwater. We don’t really see this method in the marine world. Although some experimental methods have tried to inject pressurized air for propulsion. Those methods work, but, so far, they were less efficient than conventional foil sections.

For marine propulsion, foil sections are the best option to generate a pressure difference. The shape of those foils mostly depends on ship speed. At lower speeds, straight propellers tend to be the most efficient. At higher speeds, the impeller option is best. Even the impeller largely depends on the foil section instead of centrifugal forces.