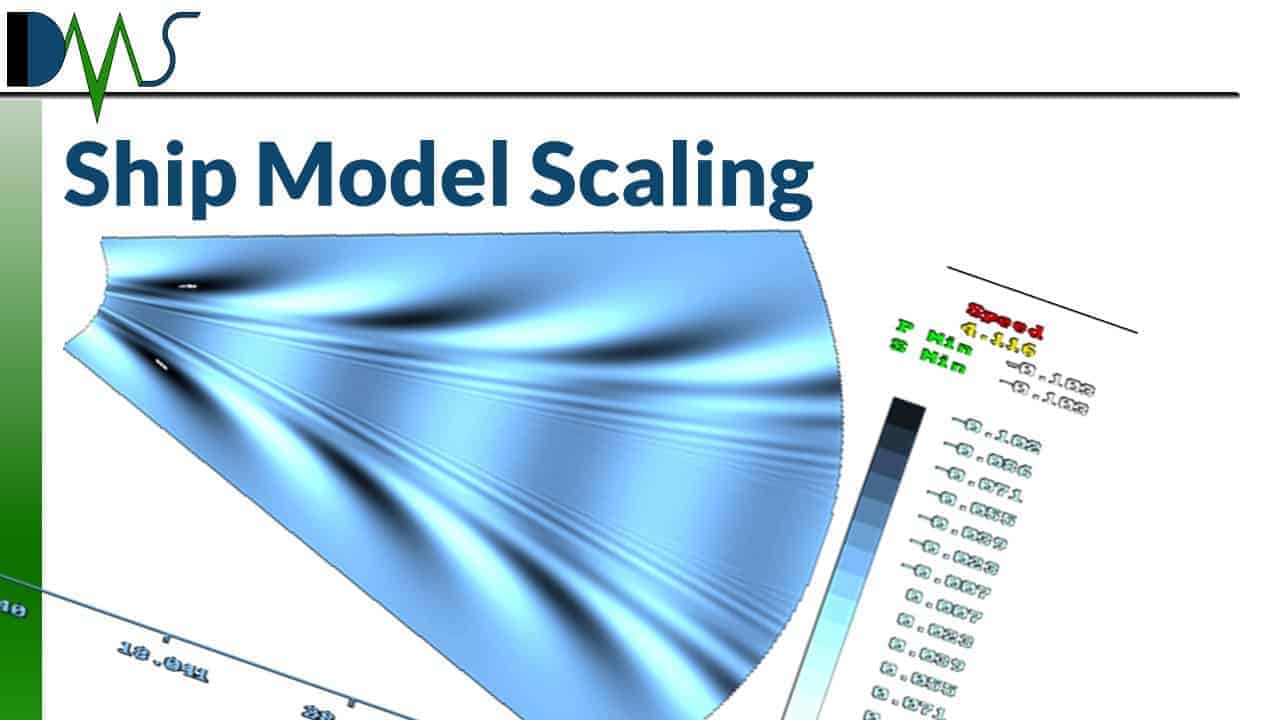

Ship Model Scaling

The physics of model scaling make it impossible to perfectly convert between model scale and ship scale. Learn how to get around the scaling correlation problem and convert from model scale to ship scale measurements.

The physics of model scaling make it impossible to perfectly convert between model scale and ship scale. Learn how to get around the scaling correlation problem and convert from model scale to ship scale measurements.

What good are model

experiments, we want big ships! Model

experiments only help if we can match those measurements to equivalent values

at the full ship scale. Easier said than

done. We developed a whole new field of

fluid mechanics just to answer this challenge.

This is where the science of modern ship design began: how to reliably convert from model scale to

ship scale.

The issues around model scaling arise because we need to

scale two different forces. Ship

resistance developed from two major forces:

viscous and waves. Viscous forces

are basically skin friction, plus some flow interactions at the stern of the

ship. The second category of forces come

from waves. These generate primarily at

the bow and the stern, creating fascinating wave patterns that change with

speed. (Figure

2‑1)

Most importantly, these two

forces behave very differently. Table 2‑1 summarizes the major differences between these two forces. (Table

2‑1 references some terms explained later in this article.) We employ entirely different rulebooks for

them. Different math, different physics,

and different formulas to convert them from model scale to ship scale.

| Viscous Forces | Wave Forces |

| Tied to fluid viscosity | Tied to gravity |

|

Force coefficient reduces with increased speed |

Force coefficient increases with increased speed |

| Reynolds number dependent | Froude number dependent |

| Dominates at low speeds | Dominates at high speeds |

Model scaling and experimental analysis are about more than just raw numbers. We seek understanding, discernible patterns, predictable behaviors. That is why naval architects usually examine resistance with another tool: non-dimensional coefficients. Non-dimensional coefficients are math formulas, used to reformat experimental data. They take the raw force of resistance and factor out ship size and speed. (This works at both model scale and ship scale.) Reformatting the data into these coefficients clarifies patterns and allows us to make meaningful comparisons between different ships.

For example, Figure 2‑1

plots raw resistance forces for a typical ship.

It’s difficult to identify significant patterns in this graph. When reviewing data, naval architects want

simple graphs so they can isolate cause and effect of any changes in our

designs.

This time, Figure 2‑2

plots the same forces, formatted as resistance coefficients. The patterns are much easier to identify and

better segmented. For example, the blue

line of the wave coefficient clearly shows three distinct regions:

That graph clearly demonstrates regions of significant

changes. Resistance coefficients make

the patterns easier to identify. And

they allow us to compare between different ships.

Resistance coefficients also work for the same ship at

different scales. This allows us to

convert from model scale to full scale.

Under the right speed conditions, we use resistance coefficients to

scale up the results, following this process:

Unfortunately, the process is far more complicated. I said that simple resistance coefficients

work under the correct speed conditions.

But physics makes it impossible to find the correct speed, thanks to

something called the scaling correlation problem.

The scaling correlation problem depends on selecting the

correct speed, and there are formulas that match model speed to ship

speed. These formulas are more

non-dimensional coefficients.

Resistance coefficients worked for forces; so we also have

non-dimensional coefficients for speed.

These speed coefficients depend on the ratios of the dominant fluid

physics in play, and we use different formulas for different situations, with

each formula generally named after the person who first developed it. For example, a submerged submarine would use

the Reynolds Number as a coefficient for speed.

Reynolds Number focuses on the ratio between the momentum of the water

and its viscosity. (The actual math is a

little more complicated than a simple ratio.)

The fathers of fluid dynamics derived several different

coefficients, based on different combinations of dominant forces. William Froude was famous for the Froude

Number, which centered around the relation between gravity and momentum of

water. The Froude Number was particularly

important to characterize waves.

These speed coefficients tied into that issue of finding the

right speed conditions. To convert from

model scale to ship scale, you need to match the speed coefficient at both scales. This ensures the correct balance between the

dominant forces at both scales, allowing you to correctly apply the force

coefficients.

And this is the crux of the scaling correlation

problem. Ship resistance is dominated by

two major forces: waves and viscous

resistance. That correlates to two

different speed coefficients: the Froude

Number and the Reynolds Number. Two

different formulas that work in opposite directions. Figure 4‑1

compares these two coefficients for different model scale factors, at a single model

speed. In theory, we could achieve the

correct speed for perfect scaling correlation at the point where these two

lines intersect.

That theory has several practical limitations. First, the intersection point changes with

each speed. To achieve perfect

correlation, we would need to construct a different model for each speed that we

wanted to test. And ship models are not

cheap, making it infeasible to build 7-10 models for a single test.

Artificial gravity is also infeasible, which is what you

would need to achieve the graph in Figure 4‑1. To create the intersection that you see in

the graph, I assumed that gravity changed between model scale and ship

scale. Mathematically, this is perfectly

valid. Practically, gravity stays approximately

the same everywhere on planet Earth, at ship scale or model scale. Unless you can invent cheap artificial

gravity, the scaling correlation problem is impossible to solve.

If we can’t solve the scaling correlation problem, we need

to get around it. The international

towing tank conference (ITTC) developed a procedure to subtract out the viscous

coefficients, so we only deal with one set of forces at a time. Now the scaling procedure goes roughly like this:

(Actually, the ITTC scaling procedure is more

complicated. But this articles only

focuses on the major concepts of the procedure.)

The ITTC correlation line was the key to solving the scaling

correlation problem. The idea for the

correlation line started with William Froude.

He towed flat plates down a tank to discover a simple formula for estimating

the viscous coefficient. (Figure

5‑1) Over the years, we improved on the work of

William Froude to develop a formula that very closely estimates the resistance

coefficient.

The key behind the ITTC correlation line is the uniform application. This formula provides a very good estimate, but not perfect. Thankfully, that doesn’t matter. Every towing tank in the world uses the same formula. Even though the formula has imperfections, every tank works with the same issues. Each tank adds on a small safety factor to correct for these imperfections, plus other complications of scaling that I have not covered. This works specifically because every tank uses the same baseline procedure as their starting point, and any additional corrections are small. Go to any decent tank in the world, and you will get nearly the same process. That consistency was the key to scaling model test results up ship scale values.

Sadly, physics makes it impossible to perfectly scale model

test results up to ship scale. But we

found a way around the scaling correlation problem. The beauty of the ITTC correlation line was

recognizing practical engineering. We

don’t need to be perfect, just close and consistent. Add in a small safety margin, and you have a

reliable method to scale from model scale to ship scale.

| [1] |

YouTube Creator, “Towing a Flat Plate,” YouTube, 26 Feb 2009. . Available: https://www.youtube.com/watch?v=G5slCVPAN1s. . |

| [2] |

A. F. Molland, S. R. Turnock and A. D. Hudson, Ship Resistance and Propulsion, 2nd edition, Cambridge, UK: Cambridge University Press, 2017. |

https://dmsonline.us/wp-content/uploads/2023/12/MackinawIce2-scaled-1.jpg

1200

985

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-01-16 09:00:002025-08-25 10:10:06Breaking the Ice: Icebreakers

https://dmsonline.us/wp-content/uploads/2023/12/MackinawIce2-scaled-1.jpg

1200

985

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-01-16 09:00:002025-08-25 10:10:06Breaking the Ice: Icebreakers https://dmsonline.us/wp-content/uploads/2022/06/Clickbait_2.66.3.jpg

1080

1920

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-08-08 06:00:002025-07-23 09:49:36Lying with Numbers

https://dmsonline.us/wp-content/uploads/2022/06/Clickbait_2.66.3.jpg

1080

1920

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-08-08 06:00:002025-07-23 09:49:36Lying with Numbers https://dmsonline.us/wp-content/uploads/2022/06/Clickbait_2.63.1.jpg

1080

1920

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-07-11 06:00:002025-08-15 10:45:34The Value of Life

https://dmsonline.us/wp-content/uploads/2022/06/Clickbait_2.63.1.jpg

1080

1920

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-07-11 06:00:002025-08-15 10:45:34The Value of Life

https://dmsonline.us/wp-content/uploads/2022/02/ClickBait1_1.84.1.jpg

1080

1920

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-02-21 06:00:002025-08-15 13:17:02Stability Letters Explained

https://dmsonline.us/wp-content/uploads/2022/02/ClickBait1_1.84.1.jpg

1080

1920

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-02-21 06:00:002025-08-15 13:17:02Stability Letters Explained https://dmsonline.us/wp-content/uploads/2021/04/Inspector.jpg

930

768

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2021-04-05 07:00:002025-08-25 10:10:06Class Societies

https://dmsonline.us/wp-content/uploads/2021/04/Inspector.jpg

930

768

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2021-04-05 07:00:002025-08-25 10:10:06Class Societies

Ship designs tailored to your mission. Engineering that advances profits.

This site uses cookies. By continuing to browse the site, you are agreeing to our use of cookies.

AcceptLearn moreWe may request cookies to be set on your device. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website.

Click on the different category headings to find out more. You can also change some of your preferences. Note that blocking some types of cookies may impact your experience on our websites and the services we are able to offer.

These cookies are strictly necessary to provide you with services available through our website and to use some of its features.

Because these cookies are strictly necessary to deliver the website, refusing them will have impact how our site functions. You always can block or delete cookies by changing your browser settings and force blocking all cookies on this website. But this will always prompt you to accept/refuse cookies when revisiting our site.

We fully respect if you want to refuse cookies but to avoid asking you again and again kindly allow us to store a cookie for that. You are free to opt out any time or opt in for other cookies to get a better experience. If you refuse cookies we will remove all set cookies in our domain.

We provide you with a list of stored cookies on your computer in our domain so you can check what we stored. Due to security reasons we are not able to show or modify cookies from other domains. You can check these in your browser security settings.

We also use different external services like Google Webfonts, Google Maps, and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site. Changes will take effect once you reload the page.

Google Webfont Settings:

Google Map Settings:

Google reCaptcha Settings:

Vimeo and Youtube video embeds: